Emulsion Flow (EF)

●Recovery of rare metals such as rare earth, Ni, Co, Li, and U from urban mine, waste waters, natural water, etc.

●Removal of toxic elements such as B, As, and radioactive elements from waste waters, drinking water, brine, etc.

●Removal of sludge, oil, and surfactant from waste water of water-based paint, oily waste water, washing waste water, etc.

●EF apparatus is produced based on the patent of the Japan Atomic Energy Agency (JAEA)

We can supply the EF extractor from a testing apparatus to a factoy

practical use apparatus at your request.

Characteristic of EF extractor

|

●Low Initial and Running Cost ・Simple Configuration and Operation by the Liquid Flow with Pump only ●Compact ・Small Size but Large Volume Processing Ability ●Easy Operation ・On/off of Pump and Open/close of Valve only ●No Oil Leakage ・Perfect Phase Separation) |

|

|

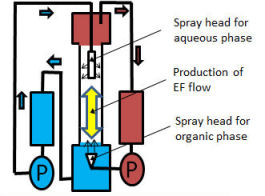

Aqueous phase is sprayed from the upper head and organic phase from the bottom head. Mixing and separation of aqueous phase and organic phase can be controlled only by the counter- current flow of both liquid with the pump. Phase separation is occurred simultaneously with extraction.

|

Testing Apparatus CMC-EF1

|

Practical use example of EF extractor

①Mixed oxide of Nd and Dy recovered from Nd magnet scrap has been

processed by the EF extractor for the separation of Dy and Nd-Pr up to

99.9% grade using PC-88A in kerosene.

(CMC company)

②Removal of U from decontamination waste water of centrifugal U

enrichment equipment using TnOA and HDEHP in kerosene. (JAEA)

③Recovery of Ni from electroless plating waste using Lix84l and PC-88A

in D70 diluent.

④Recovery of La and Gd from optical glass waste using PC-88A in

kerosene.

Specification of Testing Apparatus CMC-EF1

|

Specification of CMC-EF1 |

||

|

EF Vessel (1Tower) |

EFColumn |

PVC、68φx600 mm |

|

|

Organic Phase Separation Column |

PVC、100φx100 mm |

|

|

Aqueous Phase Separation Column |

PVC、100φx150 mm |

|

Usable Treating Solution |

|

Dilute Hydrochloric Acid, Nitric Acid, Sulfuric Acid |

|

Usable Solvent |

|

D70, Kerosene, PC-88A etc. For more detail see notice shown below. |

|

Diaphragm Pump (2Units ) |

Power |

AC100V, 30W, 3A (Max.), 50/60 Hz |

|

(See Attached Pump Manual for More Detail) |

Range of Flow Rate |

0-540 ml |

|

|

Variable Stroke |

20-100 % |

|

|

Max. Working Pressure |

0.2 MPa |

|

Reservoir Tank |

Aqueous Phase |

3.5 L |

|

|

Organic Phase |

3.5 L |

|

External Size |

|

800W X 500D X 1053H mm(Including Base Plate) |

• Please be careful to use solvent and solution damaging polyvinyl chloride.

• The extractant, diluent, and treating solution shown below are usable in this EF extraction apparatus.

|

Extractant |

PC-88A, D2EHPA, TnOA, TiOA, Lix84I, TOAB, BEPD |

|

Diluent |

D70, kerosene, octanol, decanol, n-paraffin, EHA |

|

Treating solution |

Hydrochloric acid (<38%, RT), nitric acid (<10%, RT), |

TnOA:tri-n-octylamine

TiOA:tri-iso octylamine

TOAB:tetraoctylammonium bromide

BEPD : 2-butyl-2-ethyl-1,3-propanediol

EHA : 2-ethylhexanol

If you want to use another extractant and diluent, please contact us.

Inquiries

CMC Technology Development Co., Ltd.

EF System Dept.

TEL:+81-58-379-0686 E-mail:info@cmctd.co.jp

本ページに掲載された情報、画像その他内容等の無断転載はお断りいたします。

Copyright

(C) 2004 シーエムシー技術開発株式会社. All Rights

Reserved.